The crisp air of Southeast Ontario, Canada, often signals the final push of the year's corn harvest. In a region where farming practices range from traditional to regenerative, efficiency is the key to profitability, especially when battling Canada's challenging late-season weather.

Recently, our FJD AYM system played a pivotal role in boosting the productivity of an Ottawa-area farm. This wasn't just another successful trial; it was a clear demonstration of how advanced, user-friendly technology can integrate seamlessly with classic farm machinery to deliver superior results, directly leading to an immediate four-unit order for our FJD AT2 auto steer system.

The Heart of Ontario's Corn Country

Ontario is a powerhouse of Canadian agriculture, contributing a significant portion of the country's corn production, with Eastern Ontario being a vital growing area. The corn grown here serves multiple purposes: from sweet corn destined for fresh farm stands in late summer to the vast fields of field corn (or grain/silage) used for livestock feed, ethanol production, and various industrial applications.

Corn harvesting in the Ottawa region often extends into late fall and early winter. With fields sometimes being combined right up until Christmas, the race against the weather is constant. Farmers rely on cold snaps to naturally dry the crop and stabilize machinery on wet ground. This high-stakes environment demands tools that are not only durable but supremely accurate and reliable.

Classic Machinery Meets Modern Tech

In this harvesting task, the farm utilized a setup common to large-scale North American operations:

- Combine Harvester: A robust John Deere 9600—a classic, high-capacity rotary combine from the venerable Maximizer series (late 80s-mid 90s). Known for its powerful 250hp engine and 240-bushel tank, this machine is a proven workhorse for high-throughput harvesting of various grains.

- Carting Support: A John Deere 8320 tractor was tasked with pulling a large grain cart, operating alongside the combine to facilitate 'on-the-go' unloading—a critical technique that keeps the harvester running almost non-stop, maximizing daily yield.

The entire operation—the combine stripping corn ears from the stalks and the grain carting operation—is a coordination of precision. Any inefficiency in this process, particularly due to human error in steering or the inability to monitor data accurately, results in lost time and fuel.

FJD AYM: Autosteering Combined with Yield Monitoring

Our AYM solution was deployed to tackle these inefficiencies, focusing on accuracy, data collection, and ease of use. The FJD AYM system consists of two main components:

FJD AT2 Autosteering Kit

Installed in the combine's cab, the AT2 uses advanced GNSS technology to guide the harvester with centimeter-level accuracy. This means the driver doesn't need to focus on steering and can instead watch the harvest, stopping costly mistakes like harvesting the same row twice.

FarmTRX Yield Monitoring Integration

By utilizing an optical sensor and a moisture sensor installed in the grain elevator, this FarmTRX system allows farmers to view live and average yield and grain moisture data instantly on any smartphone or tablet.

Both the AT2 and Farm TRX form our AYM solution. The result of this integration is a comprehensive, real-time picture of field performance, providing automated yield and moisture maps for every field. This critical data helps in post-harvest decision-making, such as variable-rate fertilization planning and efficient grain storage management.

Superior Performance on the Field

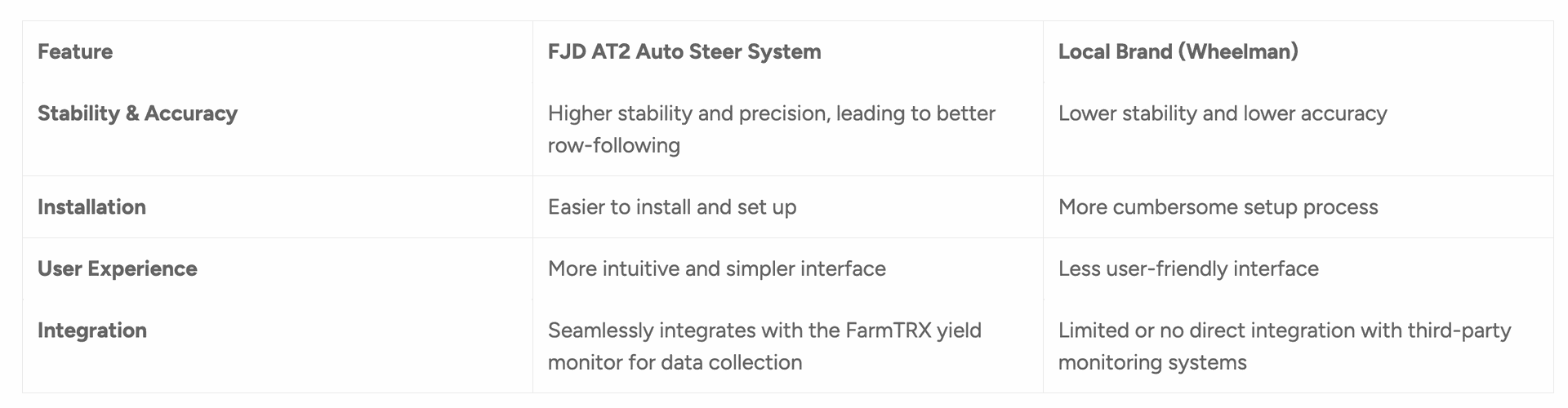

Over the course of two days, the FJD-equipped combine harvested approximately 30 hectares of corn fields. The feedback from the farmers was overwhelmingly positive, centering on a direct comparison to their previous system—the local Canadian brand. The farmers quickly discovered the distinct advantages of the FJD AT2:

The farmers specifically noted that the AT2’s higher stability and enhanced user interface were massive improvements over their previous setup.

Harvest Success Leads to Future Investment

The results were clear and easy to see: the system provided more accurate steering, the driver got less tired, and they had instant, helpful data about the crop yield. Right after the successful harvest test, the farm immediately ordered four more FJD AT2 systems. This quick new order proves the AT2 system is valuable: it gives farmers stable autosteering and data connection that is much better than the local brand they used before.

For Canadian farmers operating classic, dependable equipment like the John Deere 9600, the FJD AT2 provides an affordable and powerful path to precision agriculture. It confirms that the future of farming lies not in replacing every machine, but in intelligently upgrading proven workhorses with the best in modern guidance and monitoring technology.

Ready to upgrade your classic machinery? Discover how the FJD AYM solution can increase your harvest efficiency and data accuracy next season. Contact us today for product demos or inquiries.