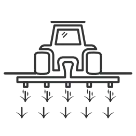

Constant Seeding Rate

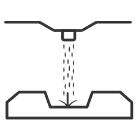

Automatic Operation Control

Quick Seeding Rate Adjustment

ISOBUS Compatibility

Precision Autosteering & Seeding

Advanced Control Algorithm

Smart Alerting Workflow

Operation Data Management

CONSISTENT SEEDING.

LESS WASTE. BETTER YIELD.

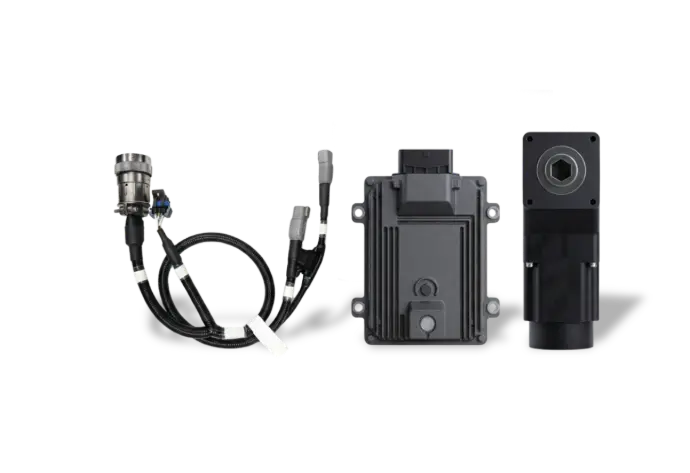

The FJD APS upgrades traditional seed drills with electric motor drive and high-precision positioning to auto-adjust seeding rates for perfect planting regardless of speed. It stops seed flow instantly at headlands by sensing implement lift/lowering, eliminating over-seeding. Compatible with any ISOBUS terminal, it transforms drills into centimeter-precision machines, saving seed and time.

ONSTANT SEEDING RATE

Utilize direct motor drive on the seed metering shaft, completely removing errors caused by wheels slipping on wet ground or sloped terrains. By matching the motor speed with the tractor's speed, it maintains a constant seeding rate per acre, ensuring that the actual seeding rate deviation stays within ±2%.

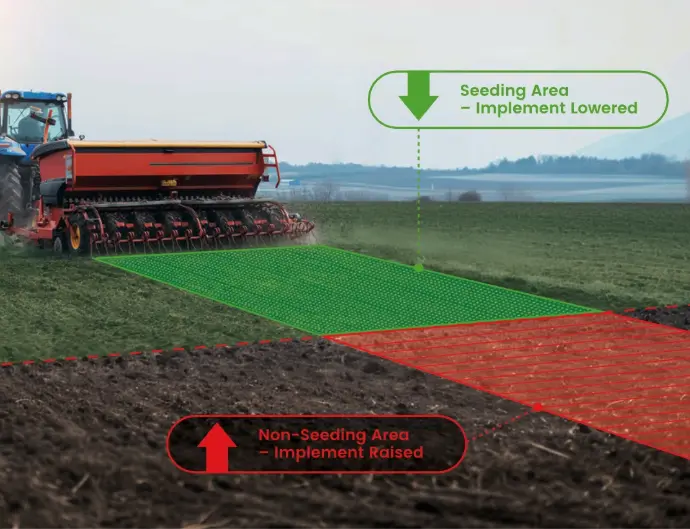

AUTOMATIC OPERATION CONTROL

etect implement raising and lowering actions to precisely control seeding. It begins planting when the implement hits the ground and stops instantly when it is lifted. This precision prevents double-planting at headlands and reduces seed waste by 3–5%.

QUICK SEEDING RATE ADJUSTMENT

Adjust the seeding rate instantly on the terminal screen, eliminating the need to stop for manual gear adjustments or time-consuming calibration tests. You can set up a new field in seconds, saving up to 15 minutes with every switch. By automatically compensating for changes in ground speed, the system maintains a steady seeding rate and prevents the accidental over-application common with manual settings. .

MART AUTOSTEERING & SEEDING

Work seamlessly with FJD autosteering systems to automate both driving and seeding with ±2.5 cm RTK precision, ensuring perfectly straight rows with zero overlaps. It also plugs directly into ISOBUS-compatible navigation terminals from other brands, offering a cost-effective way to upgrade your existing machinery with the latest smart farming technology.

SEEDING SCENARIOS

Built for spring and autumn seeding, this system is ideal for row-crop applications. It maintains consistent seeding rates and row spacing across varying field conditions and operational speeds, promoting more uniform crop emergence and growth.

QUICK SPECS

Rated Voltage |

9 - 36V |

12 V Power Output |

3A |

Digital Inputs

|

4×high/low level inputs(active-high/active-low) |

Frequency Inputs |

4 × 0–10 kHz |

Communication Protocol |

CAN |

IP Rating |

IP67 |

Sensor Type

|

Mechanical limit switch |

Output Type

|

PNP output |

Operating Voltage

|

5 - 30V DC |

Frequency Inputs |

4 × 0–10 kHz |

IP Rating |

IP65 |

Rated Input Power

|

200 W |

Rated Output Torque

|

13.4 N·m |

Rated Output Speed |

100 r/min |

IP Rating |

IP65 |

Rated Voltage |

12 VDC |

Max Current

|

20A |

Gear Ratio | 30:1 |

Operating Voltage

|

9 - 16V DC |

Operating Current |

≤ 100 mA |

Detection Method

|

Infrared optical sensing |

Detection Rate |

Up to 40–60 seeds/second |

Response Time |

< 50 ms |

Seeding Tube Diameter

|

Ø 25–35 mm |

Ingress Protection |

IP67 |

Output Interface | Pulse signal |

Operating Temperature | -20°C to 70°C |

Installation Guide