Single-Nozzle Precision.

Less Pesticide.

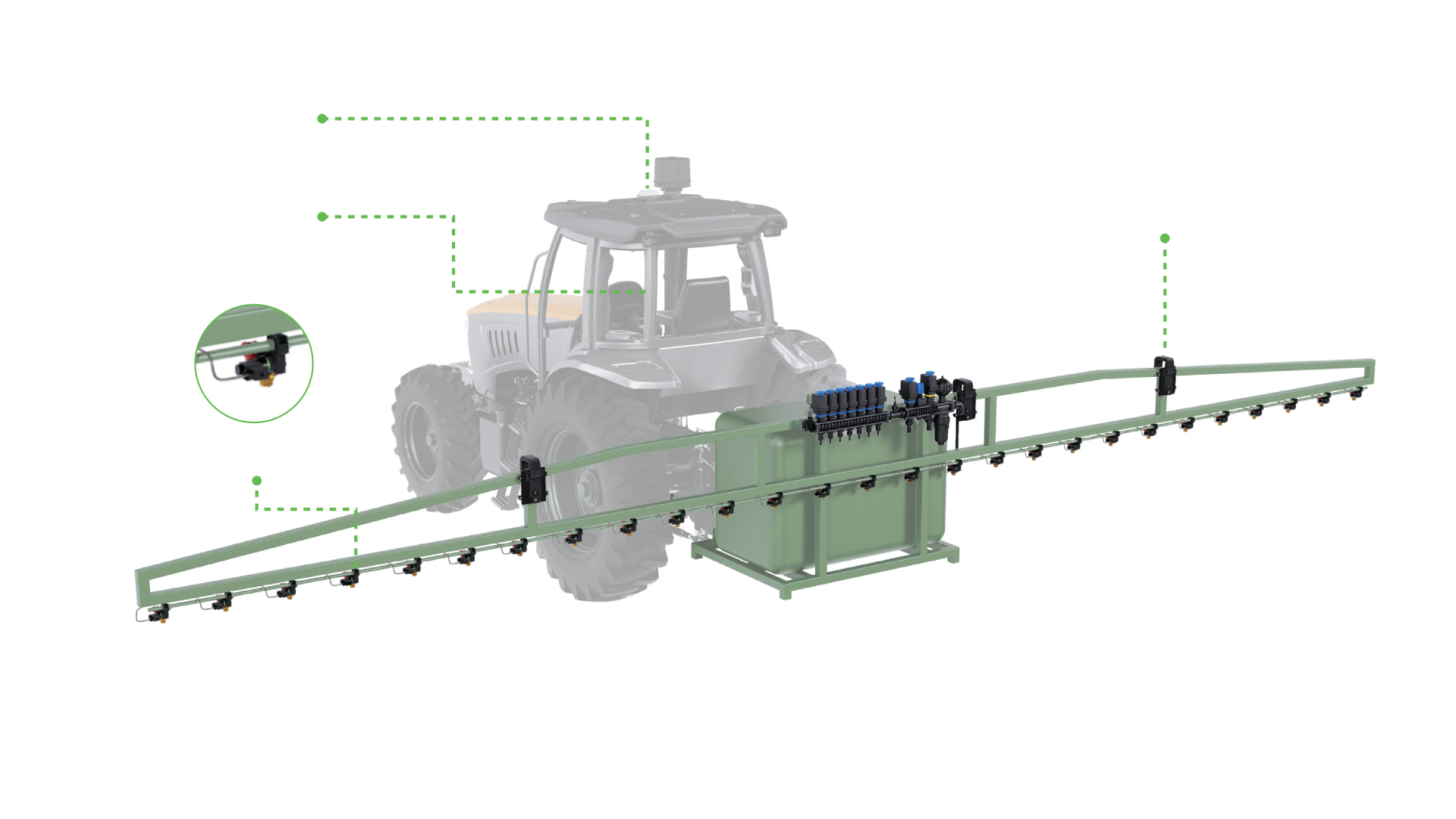

The FJD ATS Ultra is a precision spraying system featuring independent control for up to 160 nozzles. Using PWM and alternating nozzle technology, it maintains stable pressure and spray rates during turns or speed changes, greatly reducing overlaps, skips, and boundary errors. By syncing with prescription maps and ground speed, it delivers precise single-nozzle application to reduce pesticide waste and boost efficiency, making it ideal for large-scale professional farming.

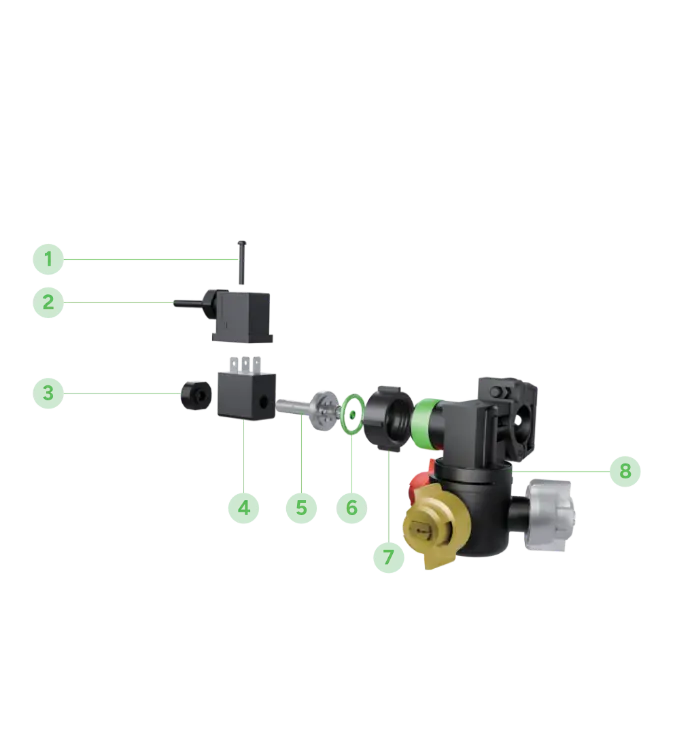

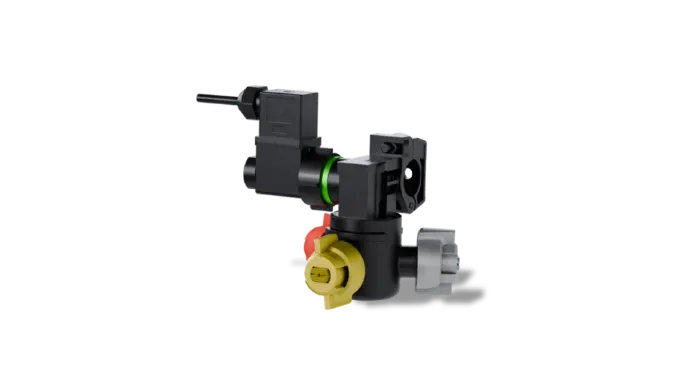

PWM SPRAY TIP CONTROL SYSTEM

How It Works: Pulse Width Modulation (PWM) adjusts the duty cycle of the nozzle's solenoid valves to control spray flow rates without changing the pressure.

Key Features: High-frequency electromagnetic control ensures fast response and high precision, and duty cycle adjustment keeps constant pressure for consistent flow rates.

Consistent Rate Control

Turn Compensation

Alternating Nozzle Operation

Variable-Rate Application

Precise Row Alignment

Sprayed Area Record

Quick Mode Switching

Real-Time Spraying Monitoring

Alternating Nozzle Operation

Optimize spray performance via high-frequency alternating control of neighboring nozzles.

Instead of turning all nozzles on/off at once, it keeps the hydraulic pressure steady and stops the spray from pulsing, delivering smoother spraying flow and better coverage across the entire field.

Without Alternate Nozzle Operation

With Alternate Nozzle Operation

Consistent Rate Control

Adjust spray rates in real time based on vehicle speed, with nozzles switching at up to 20 Hz and a duty cycle of

30%–70%. This ensures uniform coverage regardless of tractor speed.

By reading imported prescription maps, the system applies the exact prescribed rate to each zone, greatly reducing waste while boosting future yields.

Turn

Compensation

Eliminate uneven coverage caused by overspray at inner nozzles and underspray at outer nozzles during turns.

Using flow compensation algorithms, the system automatically adjusts individual duty cycles to ensure precise, consistent application across every inch of the field.

Boundary Operation Control

Turn off each nozzle individually to stay perfectly within field boundaries. This prevents spraying outside the crop area or over the edges.

Unlike section control that turns off a group of nozzles at the same time, individual nozzle control achieves cleaner edges, cutting down on chemical waste and improving operational efficiency at bound aries.

Quick Specs

Rated Voltage |

9–36V |

Electric Control Valves |

3A/12V |

Pressure Signal |

Voltage Type: 0-10V; Current Type: 0-20 mA |

Flow Signal |

0–10 kHz |

Communication Protocol |

CAN |

IP Rating |

IP67 |

Supply Voltage

|

12V |

Max Current Consumption

|

0.5A |

Duty Cycle

|

20 Hz |

Nozzle Mounting Port

|

3/4 |

PWM Control Channels

|

16 |

PWM Control Frequency

|

1Hz-1KHz |