Spraying crops is one of the most important jobs on the farm. Doing it right means protecting crops, saving money on chemicals, and getting better yields. For too long, farmers have struggled with old technology that wastes product, leaves gaps, and can't keep up with the demands of modern farming.

FJDynamics is changing that by introducing the FJD ATS Ultra PWM Spray Tip Control. This new system features individual nozzle control for more precise and consistent spraying than the traditional section control method. The ATS Ultra is a comprehensive solution for achieving perfect coverage, saving money, and moving towards more sustainable farming.

Understanding the Core: PWM Nozzle Overview

The secret behind the ATS Ultra's performance is its use of Pulse Width Modulation (PWM) technology. In a traditional sprayer, to change the flow rate (how much liquid comes out), farmers have to change the pressure. Changing the pressure changes the spray pattern, which can lead to poor coverage and drifting.

The ATS Ultra solves this by using PWM technology. This system controls the spray flow rate by rapidly adjusting how long the nozzle's solenoid valve is open (the duty cycle). Critically, this is done while keeping the hydraulic pressure constant. This means farmers can get the following benefits:

- Constant Pressure, Variable Flow: Farmers can change the amount of spray (flow rate) without changing the spray pattern.

- High Precision and Fast Response: The system uses high-frequency electromagnetic control for fast response and high precision.

The core components that make up this precise control include the Coil Assembly, Valve Core, and the Nozzle itself, all held together by a Connection Harness, Core Nut, and two O-Rings.

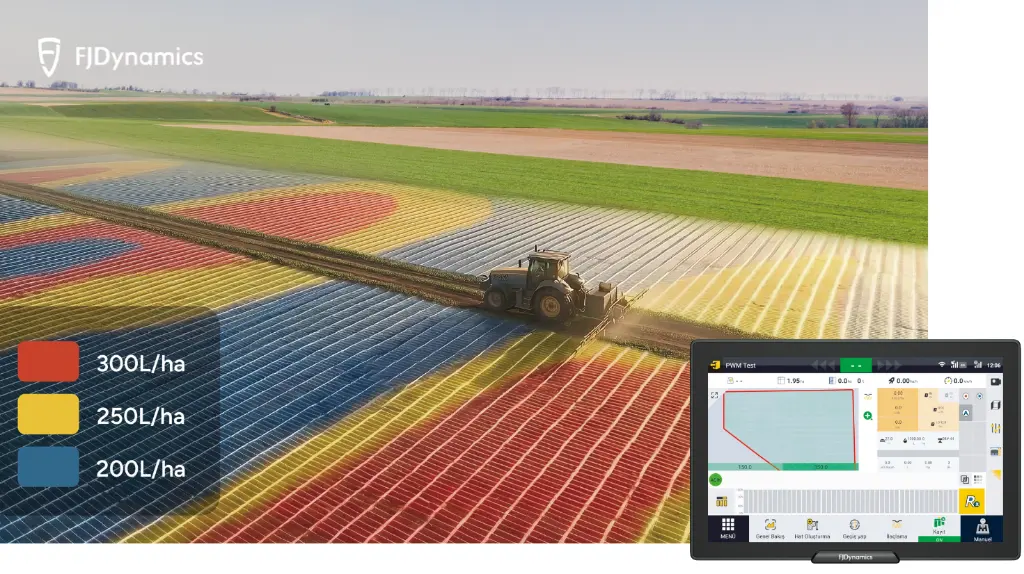

Consistent Rate Application

In the real world, the speed of a sprayer constantly changes due to hills, turns, and rough terrain. With old sprayers, when the tractor slows down, the sprayer applies too much chemical in that area (over-application). When the tractor speeds up, it sprays too little (under-application). Both outcomes hurt crop yields and waste resources.

The ATS Ultra eliminates this problem through consistent rate application. The system regulates the flow rate in real time. It constantly watches the vehicle speed and compares it to the target application rate. This ensures that the exact, correct amount of chemical is applied to every square unit of the field, no matter how much the tractor speed changes.

In this way, farmers avoid spraying too much or too little, which prevents crops from being damaged by uneven coverage and saves them money on pesticides or fertilizers.

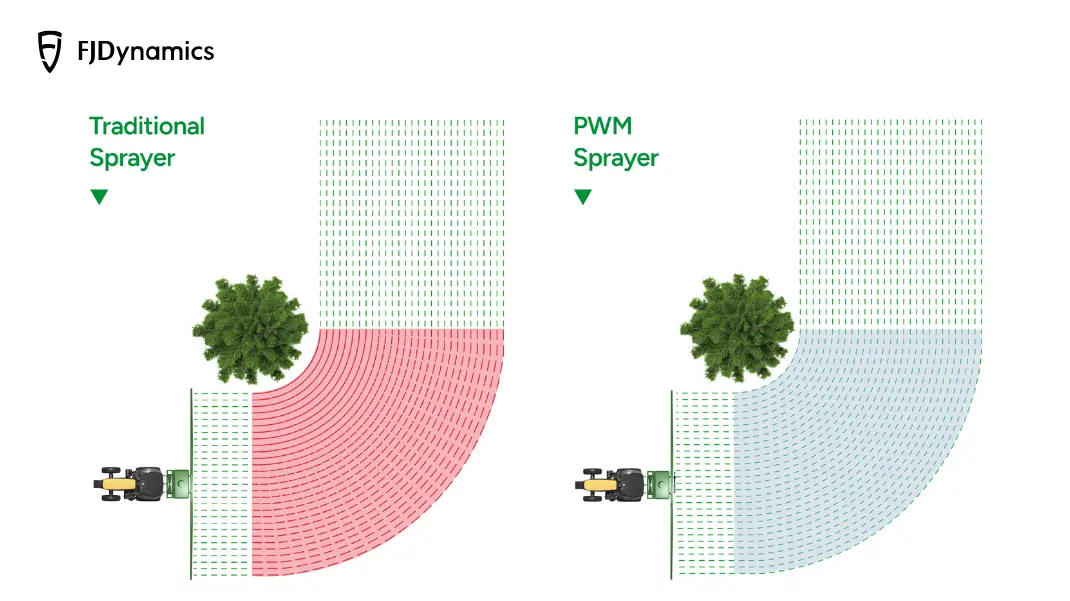

Turn Flow Compensation

Spraying around a curve or turning at the end of a row is where traditional sprayers struggle the most. When a sprayer boom turns, the nozzles on the outside of the turn must travel faster and cover more ground, while the nozzles on the inside of the turn must travel slower and cover less ground.

If all nozzles spray at the same rate, the inside nozzles will over-apply, and the outside nozzles will under-apply. The ATS Ultra uses the PWM technique to achieve turn flow compensation. It issues different duty cycles (on/off intervals) to the nozzles on the inner and outer parts of the boom during a turn.

With nozzle switching at up to 20 Hz and a modulation range covering 10%–70% duty cycle, it ensures that the spray performance remains unified and consistent across the entire boom width, regardless of the turning radius. As a result, the fields receive uniform coverage, even in sharp corners without skips or overlaps.

Alternate Nozzle Operation

One major issue with turning nozzles on and off rapidly is the effect it can have on the hydraulic system. When many solenoids open and close at the same time, it can cause the pressure in the boom line to jump up and down (pulsing). This pulsing affects the spray quality and coverage.

The ATS Ultra solves this with alternate nozzle operation. The system supports turning nozzles on/off in an alternating pattern to maintain stable hydraulic pressure. This is especially helpful in conditions where low flow is needed or spraying is done at a very low speed.

By having Nozzle A and Nozzle B open and close at slightly different times, the pump is kept under a steady load, and the pressure in the line stays stable. This stability improves how evenly the spray is atomized, resulting in better coverage.

The system controls each nozzle separately using the PWM technique, rapidly turning them on and off at varying intervals. This design ensures that overlaps are minimal and any gaps are barely noticeable.

A Long-Term Investment in Precision Spraying

The FJD ATS Ultra is a complete solution designed to eliminate the common failures of traditional section-based spraying. By combining PWM technology with key features like consistent rate application, turn flow compensation, and alternate nozzle operation, the ATS Ultra offers centimeter-level accuracy that ensures every crop gets exactly what it needs, resulting in less waste of expensive chemicals and healthier crop growth.

At FJDynamics, our mission is to bring intelligent, reliable solutions to the farm. The ATS Ultra is a long-term investment that ensures your land is cared for with the highest level of precision and sustainability.

To learn how the FJD ATS Ultra can transform your spraying operation and get a product demo or free quote, please contact us here: Contact FJDynamics