Precision agriculture is no longer just a buzzword for the future—it is the standard for the modern farm. As every farmer knows, the margins between a profitable season and a difficult one often come down to how efficiently you use your inputs. Among all the tools available today, Pulse Width Modulation (PWM) spraying is proving to be one of the most effective ways to save money, protect the environment, and ensure every acre gets exactly what it needs.

If you have ever struggled with chemical drift control, uneven coverage on turns, or the headache of changing nozzles every time your speed changes, PWM technology is designed for you. Systems like the FJD ATS Ultra are leading this charge, making high-tech spraying accessible and easy to use.

What Is PWM Spraying?

In traditional spraying, the flow rate (how much liquid comes out) is tied directly to pressure. If you want to spray more liquid because you are driving faster, the pump has to increase the pressure. Then the problem comes: higher pressure creates smaller, mist-like droplets that drift away in the wind. Lower pressure creates huge, heavy drops that roll off the leaves. You are constantly fighting to find a "middle ground" that rarely exists.

PWM: Separating Flow from Pressure

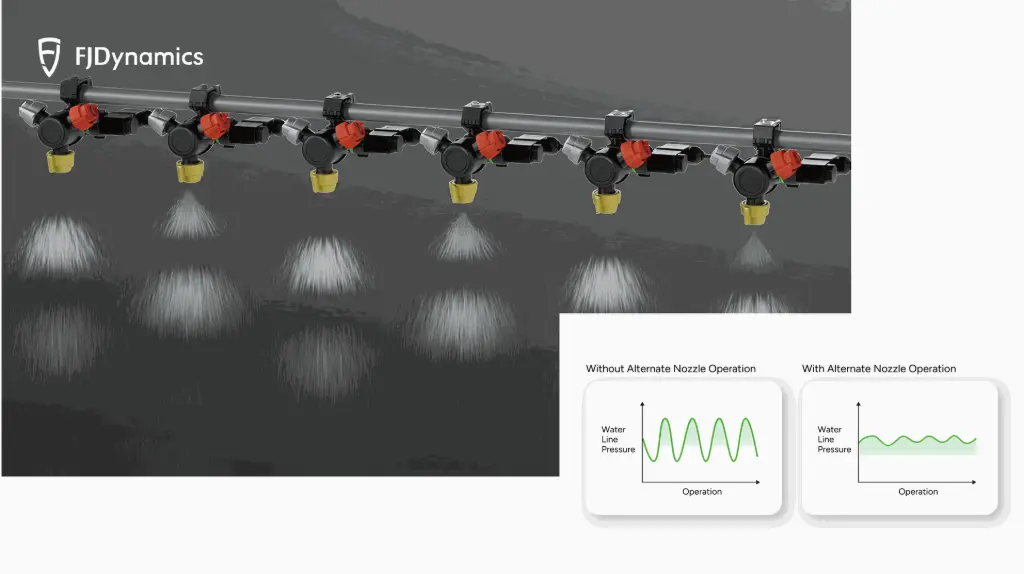

Instead of changing the pressure, a PWM system uses electronic valves (solenoids) on every single nozzle. These valves pulse open and shut many times per second. Think of it like a kitchen faucet that you flick on and off very fast.

- If the valve is open 50% of the time, you get half the flow.

- If it stays open 100% of the time, you get full flow.

Because the pulses happen so fast (measured in Hertz), the spray looks like a constant, steady stream. This allows the system to keep the pressure exactly where you want it, ensuring your droplet size stays perfect even if your tractor speeds up or slows down.

Three Critical Benefits: Why Should Farmers Care?

Switching to a system like the FJD ATS Ultra offers three immediate advantages that show up in your bottom line.

Superior Precision and Less Waste

Traditional sprayers often "over-apply" chemicals just to make sure they get enough coverage. This is expensive and bad for the soil. PWM technology allows for incredible precision. By controlling the "duty cycle" (how long the nozzle is open), the system ensures that the exact amount of chemical is applied to every square inch of the field. This efficacy means you use less resources to get better results.

Solving the Problem of Chemical Drift

Drift is a farmer's worst enemy. It wastes expensive chemicals and can damage a neighbor's crops or sensitive environments. Since PWM keeps pressure constant, you can choose a nozzle and pressure setting that produces a "coarse" or "extra coarse" droplet—the kind that hits the target and stays there. Even if the wind picks up slightly or you need to adjust your speed, your droplet size won't change, keeping the chemical on your weeds and out of the neighbor's fence line.

Turn Compensation Spraying: No More "Hot Spots"

When a sprayer boom turns a corner, the outside of the boom travels much faster than the inside. On a traditional sprayer, the inside nozzles dump too much chemical (causing crop damage), while the outside nozzles don't spray enough (leaving weeds behind).

PWM systems feature turn compensation. The system automatically tells the outside nozzles to pulse faster and the inside nozzles to pulse slower. The result is a perfectly even application across the entire width of the boom, even on the tightest turns.

Nozzle-by-Nozzle Control: The Ultimate Accuracy

The FJD ATS Ultra takes this a step further with nozzle-by-nozzle control. In the past, sprayers were controlled in large "sections." If a small part of the section hit a spot that was already sprayed, the whole section had to stay on, leading to overlap.

With individual nozzle control, the sprayer is smart enough to turn off just the specific nozzles that are over a "no-spray" zone or an area that has already been covered. This level of detail is crucial for effective pest and weed control. It ensures that you don't miss a single weed, but you also don't double-dose your crop.

Compatibility: Working With the Equipment You Already Own

One of the biggest concerns for farmers upgrading their tech is: "Will this actually work with my sprayer?" Modern PWM systems are designed to be "brand-blind." Currently, the ATS Ultra fits seamlessly with trailed, mounted, and self-propelled sprayers.

If you are already using another brand's autosteering system, FJD offers an ISOBUS solution to bridge the gap. Think of ISOBUS as a universal language for farm machinery; it allows the FJD system to plug directly into your existing consoles, whether you use John Deere, Case IH (CNH), Miller, Hardi, or Goldacres.

This compatibility makes the system future-proof. If you trade in your tractor next year for a different brand, your PWM spraying system can move right along with you. It is a scalable solution that fits everything from large self-propelled sprayers to smaller pull-type models.

The Big Picture: Data and Decisions

Precision spraying is just one piece of the puzzle. When you use a precision spray system like the ATS Ultra, you start generating valuable data. Through software like FJD FieldFusion, farmers can centralize their data. You can see exactly where you sprayed, how much you used, and what the conditions were.

This "data-driven" approach allows you to make better logistical decisions. You can track your costs down to the cent and plan your next season with total confidence. It turns your sprayer from just a machine into a powerful information tool.

Economic and Environmental Wins

At the end of the day, farming is a business. The economic benefits of PWM are clear:

- Lower Input Costs: Use less chemical by eliminating overlaps and over-application.

- Time Savings: Maintain higher speeds without losing spray quality.

- Higher Yields: Better weed and pest control leads to healthier crops.

Environmentally, it is just as significant. By reducing drift and chemical runoff, you are protecting the water and the land for the next generation. It is a rare "win-win" where doing the right thing for the planet also happens to be the best thing for your bank account.

A Simple Solution for a Complex Job

As the demand for sustainable and efficient farming grows, technologies like PWM are moving from "luxury" to "necessity." Systems like the FJD ATS Ultra and FieldFusion take the guesswork out of spraying. They allow everyday farmers to implement the best possible practices without needing a degree in computer science.

By keeping droplets consistent, stopping drift, and managing turns perfectly, PWM spraying ensures that your cropping program is as productive as possible. It is a smart, future-proof investment that helps you boost your productivity while staying a responsible steward of the land.

Ready to upgrade to PWM spraying? Contact FJD Today for an affordable solution!