Modern farming is getting smarter, and FJDynamics is excited to launch the new FJD APS Precision Seeding Control Kit. This kit is an easy upgrade that gives old seed drills incredible, centimeter-level accuracy. It helps farmers plant more evenly, stop wasting seeds, and grow better crops using the equipment they already have.

With rising costs and unpredictable weather, planting has become much harder. The FJD APS offers an affordable way to modernize seeding, the most important job on the farm. By replacing old mechanical parts with smart sensors and electric motors, the APS ensures that every seed is placed exactly where it belongs.

FJD APS Precision Seeding Control Kit

Precision Driven by Innovation

The core of the FJD APS is its ability to remove the guesswork and mechanical errors common in traditional planting. Most old-school seed drills rely on ground-drive wheels to power the seeding shaft. However, when ground conditions are wet or the terrain is sloped, those wheels slip, leading to uneven seeding and wasted potential.

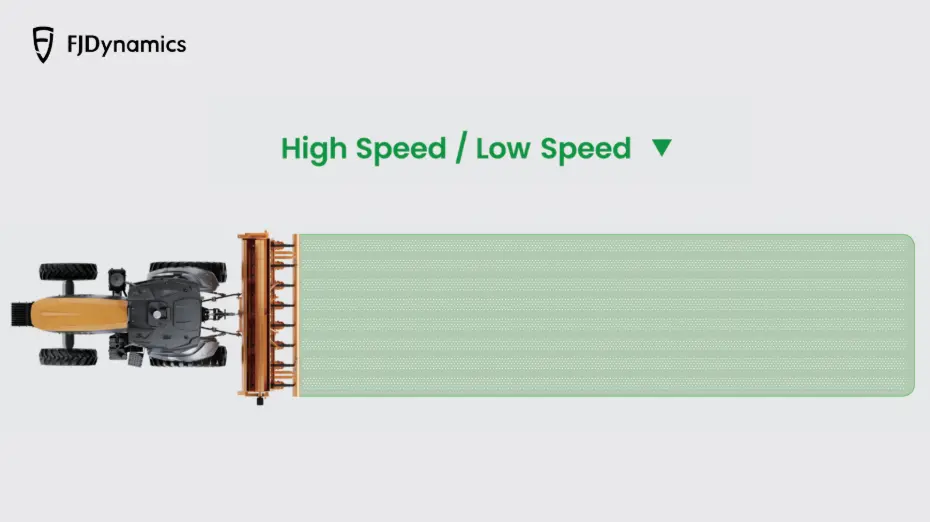

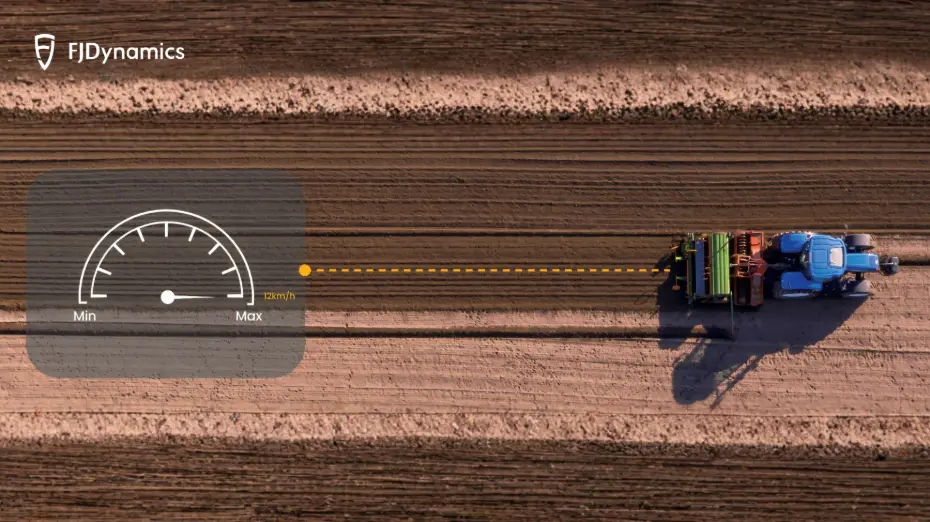

The FJD APS solves this by utilizing a direct motor drive on the seed metering shaft. By syncing the motor speed directly with the tractor's high-precision GPS speed, the system maintains a constant seeding rate regardless of how fast or slow the tractor is moving. This technology ensures that the actual seeding rate deviation stays within an impressive ±2%, providing a level of consistency that was previously impossible with mechanical systems.

Eliminating Waste in the Headlands

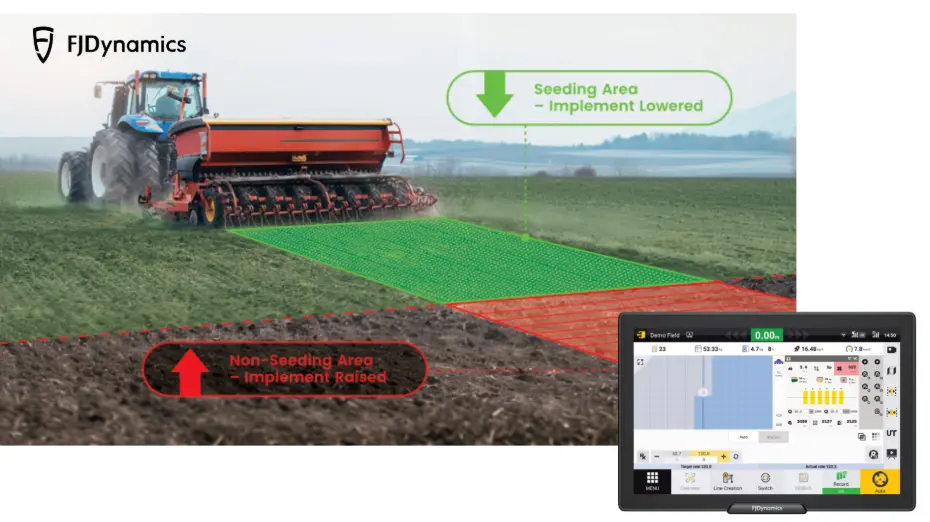

One of the most significant challenges during the planting season is overseeding at the headlands (the edges of the field). Manual operation often leads to double-planting as the tractor turns, which wastes expensive seed and leads to overcrowded crops that compete for nutrients.

The FJD APS features automatic operation control. Using a dedicated implement lift sensor, the system detects exactly when the drill is lowered into the soil and when it is raised for a turn. It begins planting the moment the implement hits the ground and stops the flow instantly when it is lifted. This precise control typically reduces seed waste by 3% to 5%, a saving that can add up to thousands of dollars across a large farming operation.

Efficiency on the Screen

Time is a farmer’s most precious resource. Traditional drills often require the operator to stop the tractor, exit the cab, and manually adjust gears or perform time-consuming calibration tests every time they change seed types or field conditions.

With the FJD APS, these adjustments are now digital. Operators can adjust the seeding rate instantly on their terminal screen. This "plug-and-play" setup allows a new field to be ready in seconds, saving up to 15 minutes with every switch. Furthermore, the system automatically compensates for changes in ground speed, preventing the accidental over-application that often occurs when a driver speeds up to beat an approaching rain cloud.

Seamless ISOBUS Integration

FJDynamics believes that technology should be accessible, not restrictive. That is why the APS Precision Seeding Control Kit is built with ISOBUS compatibility. This kit can work seamlessly with FJD autosteering systems or plug directly into existing ISOBUS-compatible terminals from other major brands.

When paired with the FJD Autosteering system, farmers can automate both the driving and the seeding with ±2.5 cm RTK precision. This creates perfectly straight rows with zero overlaps, ensuring that every inch of the field is used efficiently. It is a highly cost-effective way for farmers to upgrade their current equipment to the latest smart farming standards without having to invest in a brand-new, expensive seed drill.

Built for Every Field, Designed for Every Crop

The APS is a versatile tool built to handle the tough conditions of both spring and autumn planting across a wide range of crops. It is specifically designed to work with cereals like wheat and barley, oilseeds such as winter rapeseed, and forage crops like alfalfa. No matter the season or the crop, this system ensures consistent, reliable results for farms.

The system is comprised of four heavy-duty components designed for the harsh agricultural environment: the main controller, the implement lift sensor, the electric motor, and the seed flow monitoring module. This monitoring module is a standout feature, capable of detecting seed flow at a rate of 40 to 60 seeds per second, ensuring that if a blockage occurs, the operator knows immediately.

Promoting Uniform Growth and Higher Yields

The ultimate goal of the FJD APS is to ensure uniform crop emergence. When seeds are spaced perfectly and planted at a consistent rate, the plants do not have to fight each other for sunlight, water, and fertilizer. This leads to a healthier, more even crop stand that is easier to manage and harvest.

"The FJD APS does more than just save seed; it gives farmers peace of mind," says Nicola Xu, Product Manager at FJDynamics. "Now, farmers can look back at their old drill and know it is working with the same high precision as the newest machines on the market."

Availability

The FJD APS Precision Seeding Control Kit is available now through the FJDynamics global distributor network. For farmers looking to maximize their efficiency this coming season, the APS offers a future-proof investment that pays for itself in seed savings and improved productivity.

For product demos or inquiries, contact FJDynamics today!