Every farmer knows the feeling of looking back at a field after a pass and seeing the "hot spots"—those areas where the sprayer overlapped at the headlands, or where a point row caused a double dose of expensive chemistry. For years, farmers have accepted a certain amount of waste as the "cost of doing business." But as input prices rise and environmental regulations tighten, the margin for error is shrinking.

Today, the conversation around spraying has shifted from "how fast can we cover the ground" to "how precisely can we place the product." This has brought two technologies to the forefront: section Control and its high-tech successor, nozzle control.

If you are looking at upgrading your sprayer or buying a new one, you’ve likely asked: Is the extra investment in nozzle-level control actually worth it, or is section control plenty for what I do? Let’s break down the differences, the savings, and the reality of both systems.

Section Control: The Reliable "Wide Brush"

Section control has become the industry standard for a reason: it works. By dividing your spray boom into several segments (usually 5 to 10 sections), the system uses GPS to automatically shut off an entire section when it enters a zone that has already been sprayed.

How It Works

Think of the boom like a wide paintbrush made of several smaller brushes. If you’re painting a wall and half of your brush reaches a spot you’ve already painted, you lift that part of the brush. In the cab, your GPS/RTK system tracks your path. When Section 1 (which might be 3 meters wide, with 6 to 12 nozzles) crosses into the headland you’ve already hit, the system turns that whole section off.

FJD section control tech enables precision spraying around the world

The Benefits: Ready to Use and Cost Savings

For most broad-acre farmers growing corn, wheat, or soybeans, section control is a game-changer. It excels at preventing double-spraying in irregularly shaped fields or when finishing off a pass. On average, farmers see a 5% to 15% reduction in chemical use. This technology is ready to use for most modern setups. Its ROI is easy to calculate, and almost any dealer can service it.

The Downside: The "All or Nothing" Problem

The limitation of section control is its resolution. Because it works in sections (often 3 to 6 meters wide), it is an all-or-nothing game. If only 0.3 meters of a 3-meter section overlap a previously sprayed area, the system has a choice: keep the section on and waste chemicals, or shut it off and leave a 2.7-meter strip of weeds.

Nozzle Control: The "Fine-Tip Pen"

If section control is a wide brush, nozzle control is a fine-tip technical pen. This is the "ultimate evolution" of spraying technology. Instead of controlling a group of nozzles, the controller manages every single nozzle individually. With nozzle control, the resolution moves from meter-level to centimeter-level. Every nozzle has its own solenoid (an electronic valve) that can pulse or switch on and off in milliseconds.

Imagine a field with a random utility pole, a wet spot that needs to be skipped, or a single sensitive tree. Nozzle control can "draw" a circle around those obstacles, shutting off only the 2 or 3 nozzles that would have hit them while keeping everything else running.

When paired with AI cameras or multispectral sensors, the sprayer can identify a single weed between rows and turn on just one nozzle to hit it. This isn't just "reducing waste"—it’s "targeted hits". In high-value crops or complex fields, nozzle control can cut chemical waste by 30% to 40%.

FJD's upcoming nozzle control tech is tested in Türkiye

Section vs. Nozzle: Breaking Down the 3-Meter Section

To help you visualize the scale of the difference, let’s look at the math behind a standard 3-meter-wide boom section. In modern agriculture, the number of nozzles in this space typically ranges from 6 to 12, depending on the spacing used on the spray boom. Here is the breakdown based on standard industry spacings:

The 50 cm (20 inches) Standard

This is the most common setup for broad-acre spraying. On a 3-meter section, you would have 6 nozzles.

- Calculation: 300cm ÷ 50cm = 6 nozzles

The 25 cm (10 inches) High-Precision Standard

Many high-end systems use closer spacing for better coverage and lower boom heights. In this case, you would have 12 nozzles.

- Calculation: 300cm ÷ 25cm = 12 nozzles

Why This Matters More Than You Think

Based on different working principles, if your section is 3 meters wide:

- With Section Control: When you cross that headland, you turn off the whole 3-meter section. Even if only one nozzle (the outer 50 cm) is overlapping, all 6 or 12 nozzles shut off at once. This leaves a large unsprayed gap in your field.

- With Nozzle Control: Only that one specific nozzle shuts off. The other 5 or 11 nozzles keep working, ensuring you hit every weed without wasting a drop.

Side-by-Side: Which One Fits Your Acres?

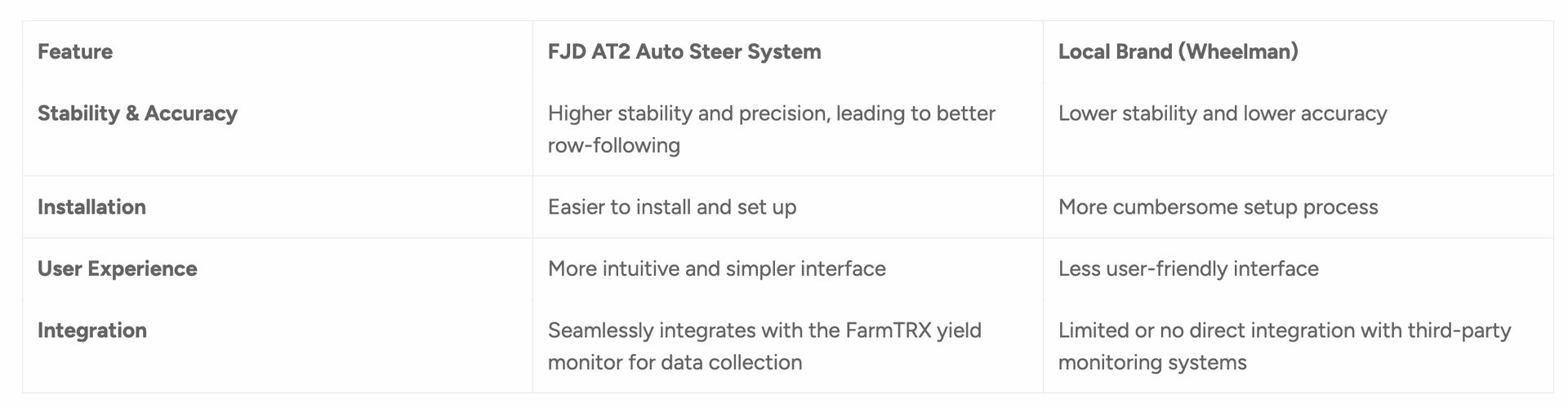

Generally, nozzle control is more precise and expensive than section control. It requires high-density electronic valves, more complex wiring, and significantly more technology retrofit to handle the data load. Here is a quick comparison between the two solutions:

Section Control: The Smart Start for Broad-Acre Farming

Therefore, if you farm mostly rectangular, flat ground and grow commodity crops like corn or wheat, section control is likely your best "bang for your buck". It solves the biggest problem (unintentional overlap) at a fraction of the cost. If you are just starting your precision agriculture journey, start here.

Nozzle Control: Precision for High-Stakes Acres

- High-Value Crops: If you are spraying vineyards, orchards, or high-end vegetables, the cost of chemical "burn" from over-application or the cost of the chemicals themselves is so high that the system pays for itself quickly.

- Complex Terrain: If your fields are full of terraces, potholes, or are shaped like "Z's" and "L's," the centimeter-level precision will save you a fortune in point-row waste.

- Environmental Pressure: If you farm near water sources or residential areas where off-target spraying is a legal liability, the ability to precisely shut off nozzles is a massive insurance policy.

Nozzle-Level Control: Precision in Every Drop

Nozzle control represents a shift in philosophy. This technology is moving away from "blanket applications" toward "individual plant management". You can think of it like this: section control is about making sure you don't spray the same spot twice. Nozzle control is about making sure you only spray exactly what needs to be sprayed.

For many farmers, section control is the "essential" tool that keeps the farm profitable today. But as we look toward a future of "see & spray" technology and stricter environmental rules, nozzle control is clearly the "Holy Grail" we are all heading toward.

If you’re looking at a new sprayer today, ask your dealer for a map of your most irregular field. Overlay a section-control pass and a nozzle-control pass. The "white space" saved on that map is the money staying in your pocket.

Thinking about an upgrade? FJDynamics can help you figure out the ROI based on your farm’s size and input costs. We have a solid track record with the ATS section control solution and are excited to launch our new nozzle control system very soon. Contact FJDynamics today to see if your current sprayer can be retrofitted with the latest nozzle-level technology.